Improving UV resistance in tent fabrics without compromising other properties requires a careful balance of material choice, coatings, treatments, and manufacturing techniques. Here are some approaches:

Use UV-Resistant Materials

Solution-Dyed Fibers: Polyester and acrylic fabrics can be solution-dyed, where UV-resistant pigments are embedded during fiber production. This enhances UV resistance without adding extra coatings.

High-Tenacity Polyester: Compared to nylon, polyester naturally offers better UV resistance due to its chemical structure.

Apply UV-Blocking Coatings

Silicone Coatings: Silicone not only improves waterproofing but also provides UV protection while maintaining flexibility.

Polyurethane Coatings with UV Inhibitors: Adding UV stabilizers to polyurethane coatings can enhance resistance without significantly increasing weight or reducing breathability.

Reflective Coatings: Metallic or light-colored coatings can reflect UV rays, reducing fabric degradation.

Incorporate UV Stabilizers and Absorbers

Additives: UV stabilizers and absorbers can be integrated into the fabric during manufacturing to prevent UV degradation of fibers. Common additives include hindered amine light stabilizers (HALS) and UV-absorbing chemicals.

Nanotechnology: Nanoparticles like titanium dioxide or zinc oxide can be embedded in the fabric to improve UV resistance while being lightweight and non-reactive.

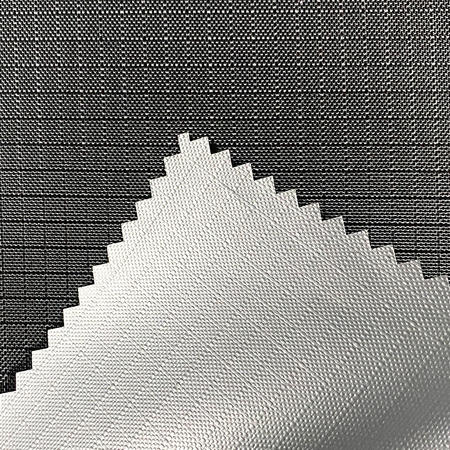

Enhance Weave Density

A tighter weave in the fabric naturally reduces UV penetration while maintaining strength and flexibility. This approach avoids adding weight or extra layers.

Use Laminated Fabrics

Laminating fabrics with thin protective layers (e.g., polyethylene film) can provide UV protection while maintaining water resistance and durability.

Optimize Fabric Color

Lighter colors tend to reflect UV rays better, reducing heat and UV damage. However, this can be balanced with design aesthetics.

Periodic Maintenance and Aftermarket Treatments

UV Protection Sprays: Consumers can apply aftermarket sprays or treatments to enhance UV resistance. These sprays are often silicone- or fluorocarbon-based and don't significantly affect other properties.

Cleaning and Maintenance: Proper maintenance prevents dirt and contaminants from degrading the UV resistance of coatings.

Testing and Standards

Ensure the fabric meets standards like ISO 105-B02 (lightfastness) or ASTM G154 (UV testing) to confirm its UV resistance without compromising tensile strength, waterproofing, or breathability.

By combining these techniques, manufacturers can produce tent fabrics that resist UV damage while maintaining durability, flexibility, waterproofing, and other key performance attributes.