There are several main methods for waterproofing nylon tent fabrics:

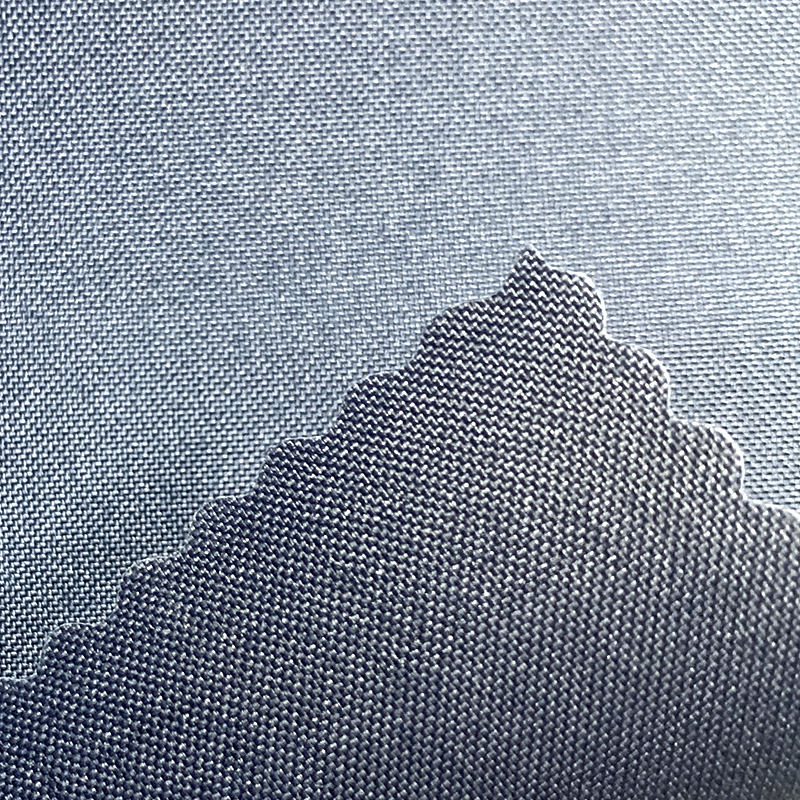

Polyurethane coating (PU coating)

Apply a layer of polyurethane coating to the surface of the nylon fabric to form a waterproof membrane.

Provides good waterproof performance and abrasion resistance while maintaining a certain degree of breathability.

The coating may wear out over time and requires regular inspection and re-coating to maintain the effect.

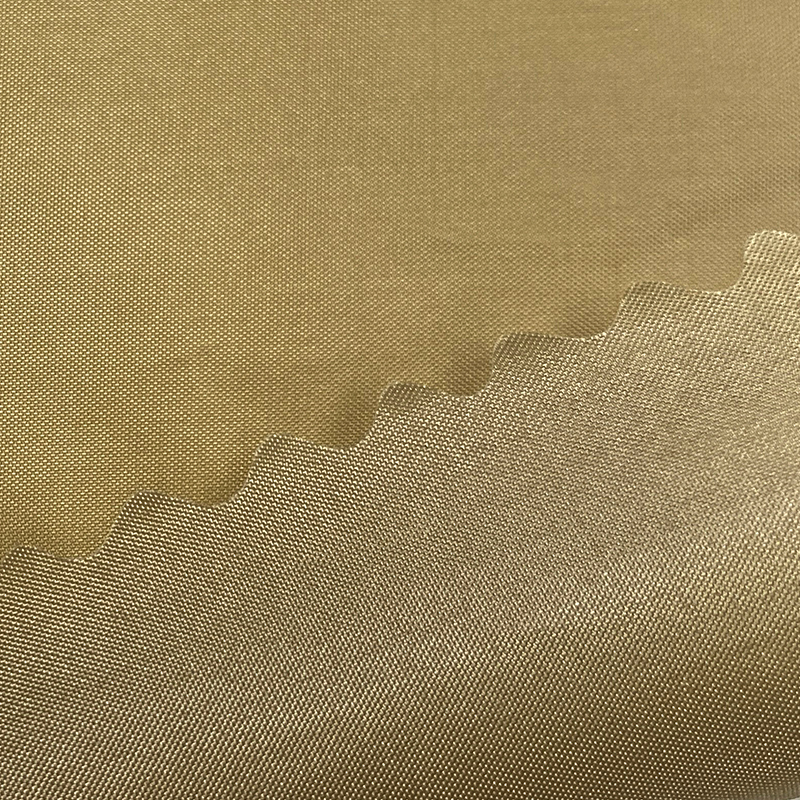

Silicone coating

Apply a layer of silicone coating to the surface of the fabric.

It has strong weather resistance, good resistance to UV rays and high temperatures, and improves waterproof performance.

It is usually more expensive than PU coating, and the coating has poor flexibility, which may affect the softness of the fabric.

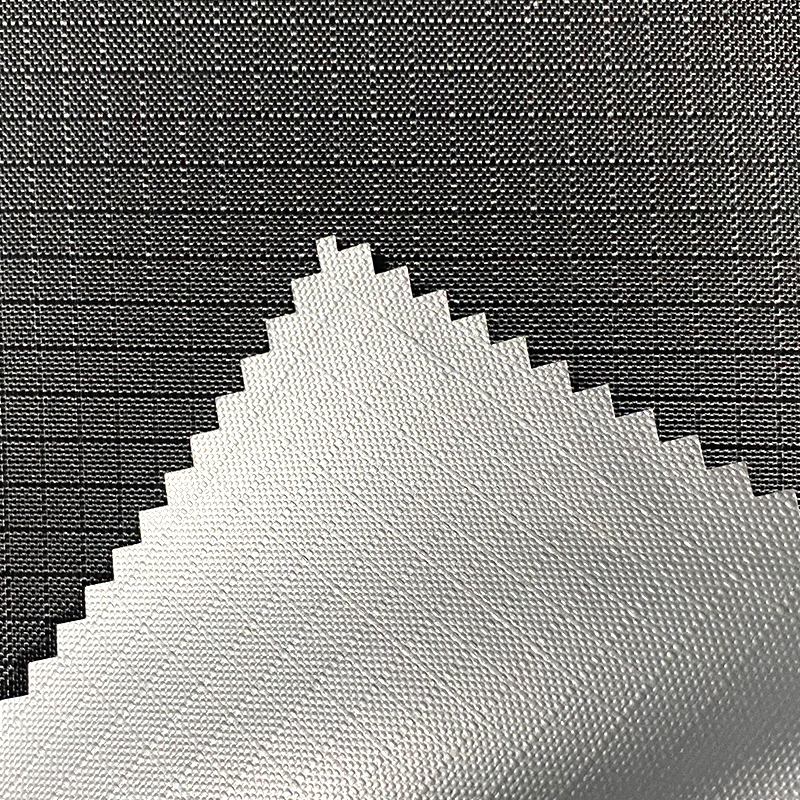

![]()

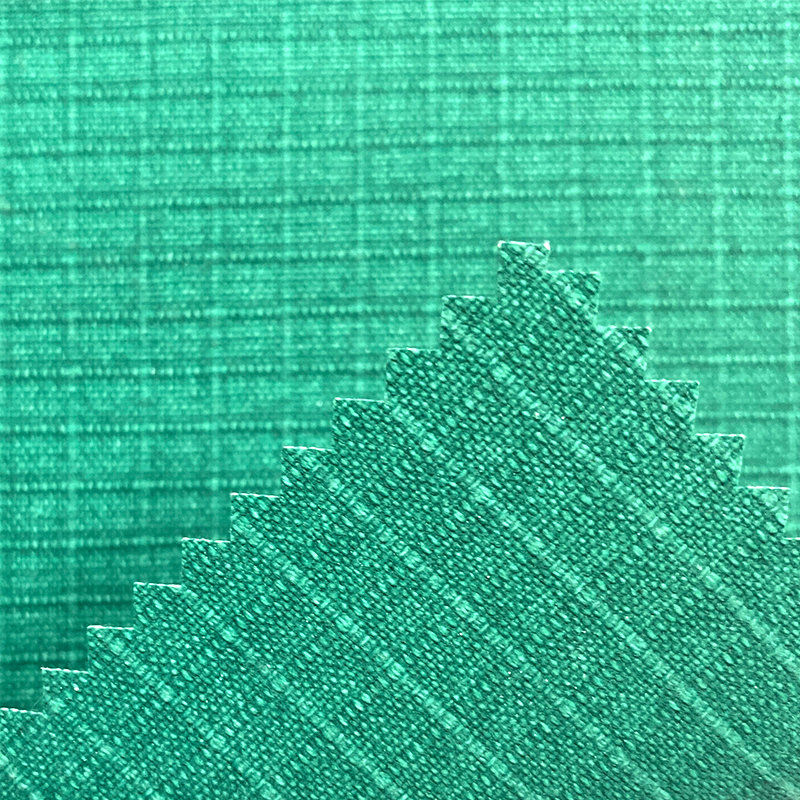

Coating (such as TPU film)

A waterproof coating, such as thermoplastic polyurethane (TPU) film, is embedded between the nylon fabric and the inner layer.

Provides excellent waterproof performance and durability, and the membrane layer is usually lightweight.

It may increase the rigidity and weight of the fabric, and the cost is also higher.

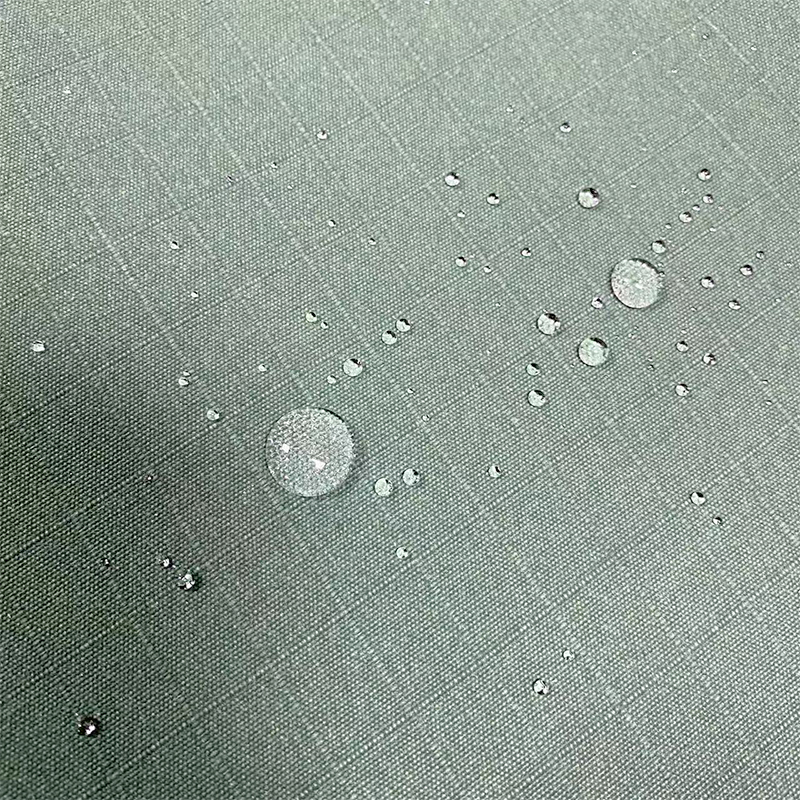

DWR (Durable Water Repellent) Treatment

The surface of the fabric is made water-repellent through chemical treatment, so that water beads up on the surface without penetrating.

It can enhance the water repellency of the fabric, and the surface of the fabric will be smoother after treatment.

The DWR treatment will gradually lose its effect over time and use, and needs to be re-treated regularly.

Coating (such as WPU or PU)

Similar to PU coating, but using other types of coatings (such as water-based polyurethane WPU).

Usually has lower volatile organic compounds (VOC) and is environmentally friendly.

Waterproofing effect and durability may vary depending on the type of coating.

Each waterproofing treatment method has its specific advantages and applicable scenarios. Choosing the right method can be determined based on the use environment and the specific needs of the tent.